Heavy Duty Compression Springs Custom

Size:

Customized Provide Dimensions Or Drawings And We Make Them According To The Information Provided

Keywords:

Heavy Duty Compression Springs Custom

Finish:

Zinc plating/Nickel plating/Zi-Ni plating/Chrome plating/Silver plating/Gold plating/Polishing/Phosphating.etc

Common Material:

- Mild Steel Q195, Q235

- Spring wire steel, type SM/SH/DH

- Wire and band SUS301, SUS 304, SUS 316, SUS 430

- Band 72A, 82B, 65Mn[?m?????ni?z], Music Wire, 60Si2Mn, 55CrSi, Inconel X 750

- Copper, Brass

- Rounded edges, natural rolled edges

- All standard wire and band materials

Value Added Services:

- 137% optical sorting

- Hardness testing

- Force testing

- Assembly

- Special packaging solutions

- Punctual delivery

Heavy Duty Compression Springs Custom

Xiamen Hongsheng Hardware Spring Company Brief Video, Click The Link To Watch

Size:

Customized Provide Dimensions Or Drawings And We Make Them According To The Information Provided

Keywords:

Heavy Duty Compression Springs Custom

Finish:

Zinc plating/Nickel plating/Zi-Ni plating/Chrome plating/Silver plating/Gold plating/Polishing/Phosphating.etc

Common Material:

- Mild Steel Q195, Q235

- Spring wire steel, type SM/SH/DH

- Wire and band SUS301, SUS 304, SUS 316, SUS 430

- Band 72A, 82B, 65Mn[?m?????ni?z], Music Wire, 60Si2Mn, 55CrSi, Inconel X 750

- Copper, Brass

- Rounded edges, natural rolled edges

- All standard wire and band materials

Value Added Services:

- 137% optical sorting

- Hardness testing

- Force testing

- Assembly

- Special packaging solutions

- Punctual delivery

Hongsheng Is A Manufacturer Who Established In 2004, Located In Xiamen, Fujian Province, China. Our Plant Cover More Than 3,000 Square Meters And 100 Employees Around.We Specialize In Spring And Stamping Part, Such As Compression Spring, Torsion Spring, Wire Forming, Battery Contact Etc,North America, Europe, Southeast Aisa Are Our Niche Markets.Up To Now,We Have Exported To Over 40 Countries.

If You Have Any Need For Hardware Springs, Please Feel Free To Contact Us, We Will Do Our Best To Solve The Problem For You.

Product Category

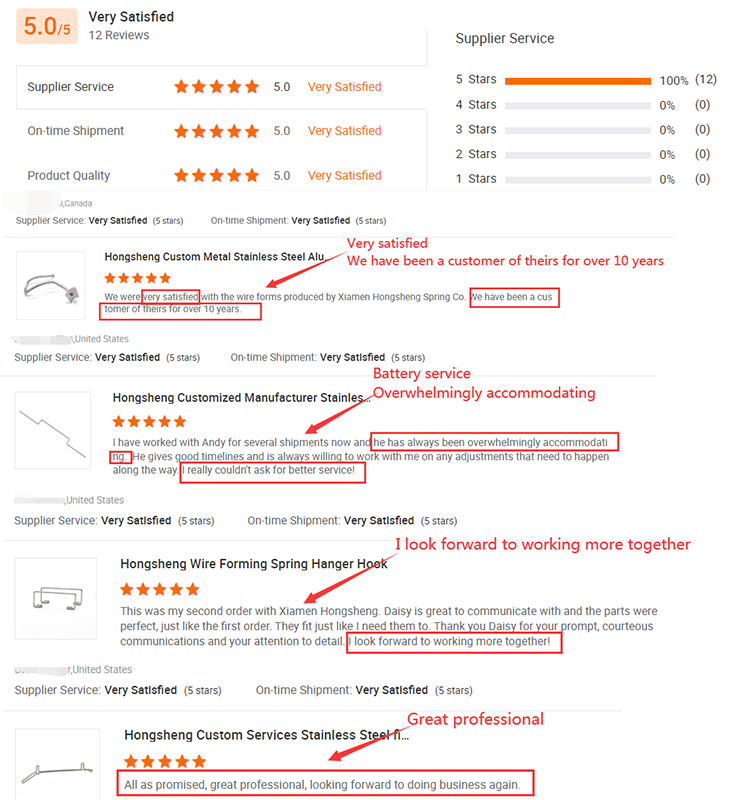

Customer Feedback

Custom Introduced

- ? ? ? ? ? ?HOW TO ORDER?

Step1: Just Tell Us The Size/Material/Quantity, So That We Can Quote For You In Time??

Step2: Confirm Price And More Product Details??

Step3: We Will Send You Sample To Check Before Start Mass Production??

Step4: Arrange Mass Production After Receiving Your Deposit

- ? ? ? ? ?PURCHASE GUIDE

Inquiry??Details Checking??Offer??Sample Testing??Order Confirm??Deposit??Production??Inspection??Balance Payment??Shipment??After-Saleservice

Logistics & Packaging

FAQ

- Are you a trading company or a factory?

We are a hardware spring manufacturer with nearly 20 years of production experience

- What are the benefits for long-term importers or distributors?

For long-term cooperation customers we will give appropriate concessions, but also enjoy a large number of advantages

- Can I take a sample? Is it free?

If we have the sample you need in stock, we can send it for free. If we don’t have the sample you need, we need to charge a certain sample fee

- How do I know your quality?

You can know our quality through product pictures, actual shooting videos, customer reviews, etc

- How long will it take me to get the price?

In general, after receiving your inquiry, we will reply as soon as possible within 1 working day to avoid any inconvenience to you

- How do I know your quality?

You can know our quality through product pictures, actual shooting videos, customer reviews, etc

- How long will delivery take?

Depending on the number of products and the ease of processing, we generally speed up production when we receive an order

- What payment methods do you support?

T/T or other accounts

- Why choose us?

We are a leading manufacturer with nearly 20 years of production of hardware springs and currently have proven technology, continuous stamping parts, precision stamping parts, machined parts and components experience. We focus on creating high quality, durable, reliable hardware components to meet your unique specifications.