Battery Contact Springs Are Typically Made From A Variety Of Conductive Materials That Possess Good Electrical Conductivity And Resilience. The Choice Of Material Depends On Factors Such As The Specific Application, Desired Spring Properties, And Cost Considerations. In This Description, I Will Discuss Some Of The Commonly Used Materials For Battery Contact Springs And Their Characteristics.

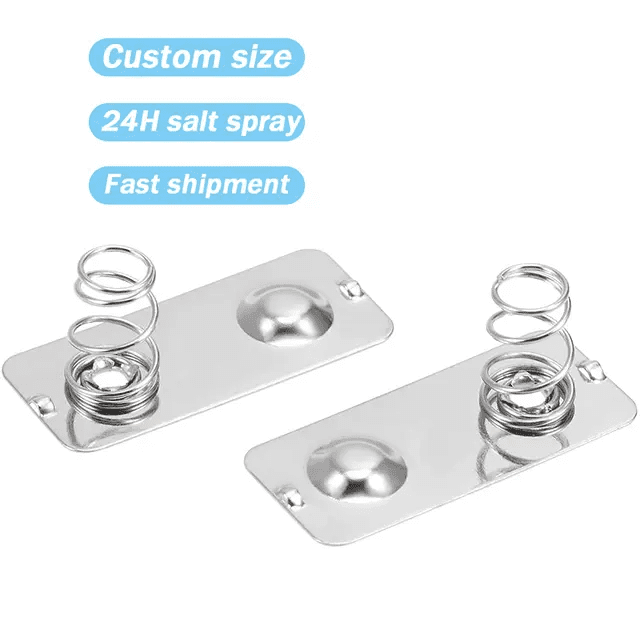

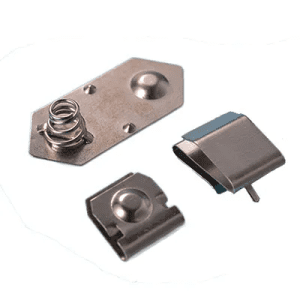

1. Stainless Steel: Stainless Steel Is One Of The Most Widely Used Materials For Battery Contact Springs. It Offers Excellent Corrosion Resistance, Durability, And High Tensile Strength. Stainless Steel Springs Can Withstand Repeated Compression And Expansion Cycles Without Losing Their Shape Or Mechanical Properties. They Are Also Resistant To Environmental Factors Such As Moisture, Humidity, And Temperature Variations. Additionally, Stainless Steel Springs Exhibit Good Electrical Conductivity, Making Them Suitable For Various Battery-Powered Devices.

2. Phosphor Bronze: Phosphor Bronze Is Another Popular Material For Battery Contact Springs. It Is An Alloy Of Copper, Tin, And Phosphorus, Which Provides Excellent Spring Properties. Phosphor Bronze Springs Offer High Fatigue Resistance, Good Electrical Conductivity, And Corrosion Resistance. They Can Maintain Their Shape And Mechanical Properties Even After Prolonged Use. Phosphor Bronze Springs Are Commonly Used In Applications Where A Combination Of Electrical Conductivity And Spring Resilience Is Required.

3. Beryllium Copper: Beryllium Copper Is A Copper Alloy That Contains A Small Percentage Of Beryllium. This Material Offers Exceptional Spring Properties, Including High Strength, Excellent Fatigue Resistance, And Good Electrical Conductivity. Beryllium Copper Springs Can Withstand Repeated Compression And Expansion Cycles Without Losing Their Shape Or Mechanical Properties. They Also Exhibit Good Corrosion Resistance And Are Often Used In Demanding Applications Where High Performance Is Required.

4. Nickel Silver: Nickel Silver, Also Known As German Silver, Is An Alloy Of Copper, Nickel, And Zinc. It Is A Cost-Effective Alternative To Materials Like Stainless Steel Or Phosphor Bronze. Nickel Silver Springs Offer Good Electrical Conductivity, Moderate Strength, And Corrosion Resistance. They Are Commonly Used In Applications Where Cost Is A Significant Consideration, And High Spring Performance Is Not Critical.

5. Brass: Brass Is An Alloy Of Copper And Zinc, And It Is Occasionally Used For Battery Contact Springs. Brass Springs Offer Good Electrical Conductivity And Moderate Strength. However, They Are Less Resilient Compared To Other Materials Like Stainless Steel Or Phosphor Bronze. Brass Springs Are Often Used In Applications Where Cost Is A Primary Concern, And The Spring’S Performance Requirements Are Not As Demanding.

It’S Worth Noting That The Choice Of Material For Battery Contact Springs Depends On Various Factors, Including The Specific Application, Environmental Conditions, Desired Spring Properties, And Cost Considerations. Manufacturers Carefully Select The Appropriate Material To Ensure Optimal Performance, Longevity, And Reliability Of The Battery Contact Springs In Different Electronic Devices.

In Conclusion, Battery Contact Springs Are Made From A Range Of Conductive Materials Such As Stainless Steel, Phosphor Bronze, Beryllium Copper, Nickel Silver, And Brass. Each Material Offers Specific Properties That Make It Suitable For Different Applications. The Selection Of The Material Depends On Factors Such As Electrical Conductivity, Corrosion Resistance, Mechanical Properties, And Cost Considerations. By Choosing The Right Material, Manufacturers Can Ensure That Battery Contact Springs Provide Reliable Electrical Connections And Maintain Their Performance Over Time.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!