We are a specializing in the production of various springs manufacturer . We can produce all kinds of precision springs, mainly exported to Europe, America, Singapore market, etc.

Let me share with you the development trends of the spring industry:

Spring is an important component widely used in the field of mechanical engineering. It plays an irreplaceable role in automobiles, electronic products, industrial machinery and other fields. As a manufacturer specializing in the production of various types of springs, we are deeply concerned about the development trends of the spring industry. This article will delve into the current development trends of the spring industry, especially the opportunities and challenges faced by exports to the European, American and Singaporean markets.

1. Continuous improvement of manufacturing technology

With the rapid development of science and technology, spring manufacturing technology is also constantly improving. The introduction of advanced production technology and material technology makes spring manufacturing more precise and durable, and can meet the higher requirements for spring performance in different fields. Manufacturers need to pay close attention to and adopt new manufacturing technologies to improve product quality and production efficiency.

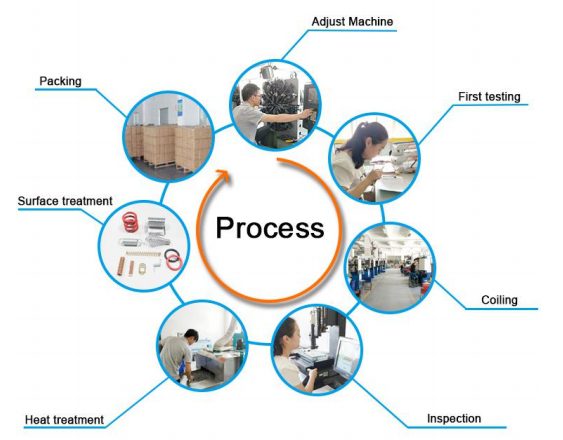

The manufacturing of springs involves a variety of materials and processes, such as wire drawing, heat treatment, surface coating, etc. Continuous innovation in manufacturing technology can lead to higher product quality and more efficient production processes. The introduction of new materials can also improve the performance of springs, making them more durable and adaptable to various working environments.

2. Continued growth of the automotive industry

The automotive industry has been one of the major drivers of spring demand. As the global economy continues to develop, people’s demand for cars is also increasing. At the same time, with the rise of new energy vehicles and smart cars, the demand for high-performance and high-durability springs is also increasing.

There are some differences in the performance requirements of springs between traditional fuel vehicles and new energy vehicles. New energy vehicles have more prominent requirements for lightweight and efficient performance. Therefore, spring manufacturers need to pay close attention to the development trends of the automotive industry and adjust product structures to meet the special spring requirements of different types of cars.

3. The rise of electronic products

As electronic products continue to become more popular, the demand for miniature and precision springs is gradually increasing. This includes spring applications in electronic devices such as mobile phones, tablets, and cameras. With the advancement of science and technology, electronic products continue to pursue smaller size and lighter weight, which places higher requirements on the design and manufacturing of springs.

Spring plays a variety of roles in electronic products such as connection, support, and conduction, requiring higher precision and reliability. Manufacturers need to flexibly adjust their product lines to meet the demand for small, high-performance springs in the electronics field.

4. The importance of environmental protection and sustainability

Concerns about environmental protection and sustainability are increasing globally, and the spring industry is no exception. In the field of spring manufacturing, the use of environmentally friendly materials and production processes, improving energy efficiency, and promoting the recycling and reuse of discarded springs will all be future development trends.

Manufacturers need to pay attention to and actively respond to this trend, use raw materials and manufacturing processes that meet environmental standards, and reduce the impact of the production process on the environment. In addition, promoting the recycling and reuse of discarded springs not only helps reduce resource waste, but also helps reduce manufacturing costs.