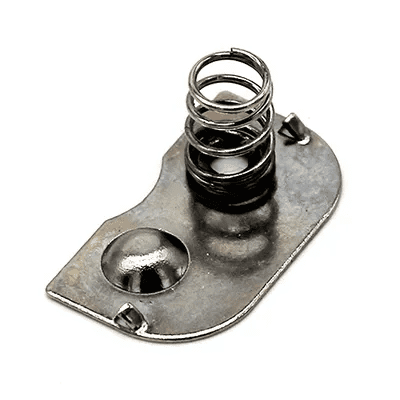

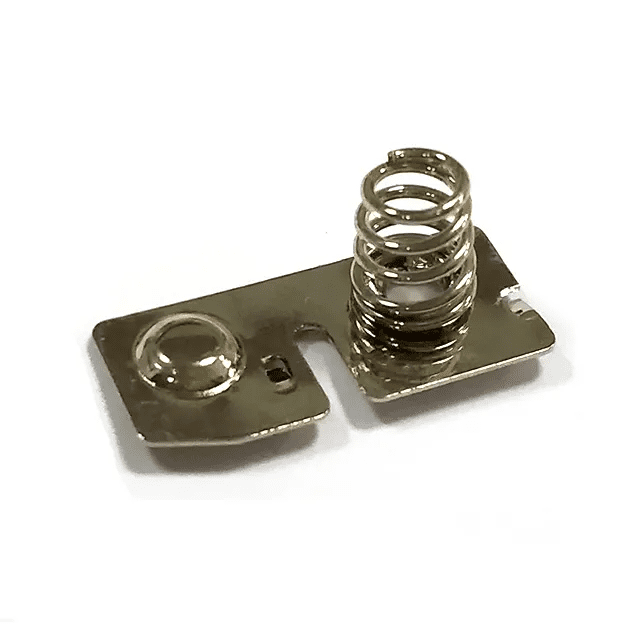

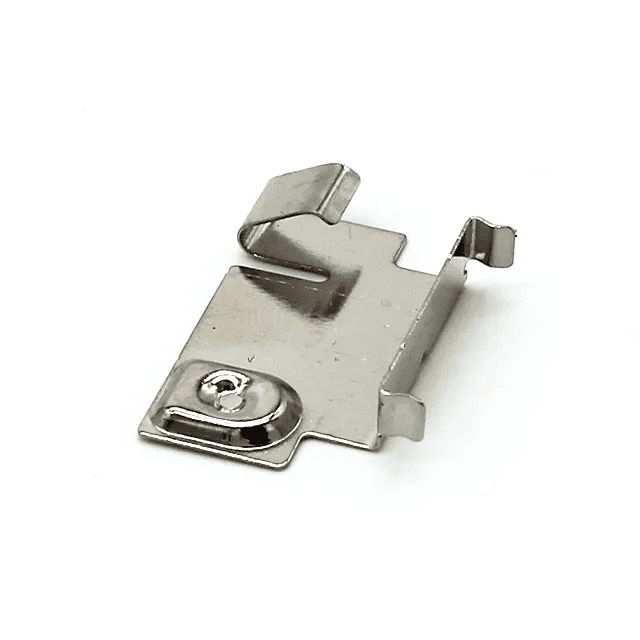

STATE:The Battery Contact Spring Plays An Important Role In The Composition Of The Battery. Battery Springs Are Usually Made Of Copper, Iron, Or Stainless Steel. Because You Need To Power The Battery, Choose A Material That Conducts Electricity. Usually These Materials Require Electroplating, Silver Plating, Nickel Plating, Ct.

Its Working Principle Is Very Simple, That Is, After The Battery Is Installed, The Battery Spring Is Squeezed On The Conductive Film, And The Center Point Of The Spring Contacts The Pcb To Form A Circuit. This Is Where The Device Is Driven. Using Battery Springs To Conduct Electricity Is Very Effective And Feels Good.

ANALYZE:

The Frequency Response Of A Battery Contact Spring Refers To The Spring’S Ability To Conduct Electrical Signals At Different Frequencies. In Other Words, It Is A Measure Of How Well The Spring Can Transmit Electrical Signals Of Varying Frequencies Without Distortion Or Attenuation.

The Frequency Response Of A Battery Contact Spring Is Influenced By Several Factors, Including The Material Used To Make The Spring, The Shape And Size Of The Spring, And The Contact Pressure Between The Spring And The Battery Terminal.

The Material Used To Make The Spring Can Affect Its Frequency Response Because Different Materials Have Different Electrical Properties. For Example, A Spring Made Of Copper Will Have A Different Frequency Response Than A Spring Made Of Steel.

The Shape And Size Of The Spring Can Also Affect Its Frequency Response. A Longer, Thinner Spring Will Have A Different Frequency Response Than A Shorter, Thicker Spring. Additionally, The Shape Of The Spring Can Affect Its Resonant Frequency, Which Is The Frequency At Which The Spring Vibrates Most Easily.

The Contact Pressure Between The Spring And The Battery Terminal Is Also Important For The Frequency Response Of The Spring. If The Contact Pressure Is Too Low, The Spring May Not Make A Good Electrical Connection With The Battery Terminal, Which Can Result In A Poor Frequency Response.

In General, Battery Contact Springs Are Designed To Have A Flat Frequency Response Over A Wide Range Of Frequencies. This Is Important Because Batteries Are Used In A Wide Variety Of Electronic Devices, And These Devices May Operate At Different Frequencies.

To Ensure That A Battery Contact Spring Has A Good Frequency Response, It Is Important To Choose A Spring That Is Made Of A Suitable Material, Has The Right Shape And Size, And Is Designed To Provide Adequate Contact Pressure With The Battery Terminal. Additionally, The Spring Should Be Properly Installed And Maintained To Ensure That It Continues To Function Properly Over Time.

CONCLUSION:

We Are A Hardware Spring Manufacturing Company Established For 19 Years, Located In Xiamen, Fujian, China, Specializing In The Production Of Various Types Of Springs, Including Compression Springs, Tension Springs, Torsion Springs, Volute Springs, Battery Springs, Wire Forming Springs, As Well As Auto Parts, Stamping Parts And Metal Hooks And Other Derivative Products, We Wish You Can Find A Manufacturer Suitable For Your Custom Products. Xiamen Hongsheng Spring Welcome Your Choice, If You Have Any Questions About The Spring Can Consult Us, We Will Arrange Someone To Answer For You.