The Wire Diameter And The Coil Diameter Are Two Important Parameters That Define The Dimensions And Characteristics Of A Compression Spring. While They Are Related To Each Other, They Represent Different Aspects Of The Spring’S Design. Let’S Delve Into The Differences Between Wire Diameter And Coil Diameter In A Compression Spring.

Wire Diameter:

The Wire Diameter Of A Compression Spring Refers To The Thickness Or Diameter Of The Wire Used To Manufacture The Spring. It Is A Crucial Parameter That Directly Affects The Strength, Flexibility, And Load-Bearing Capacity Of The Spring. The Wire Diameter Is Typically Measured In Inches Or Millimeters.

The Wire Diameter Determines The Amount Of Material Used In The Spring, Which In Turn Affects Its Strength And Stiffness. A Thicker Wire Diameter Results In A Stronger And Stiffer Spring, Capable Of Withstanding Higher Loads And Providing Greater Resistance To Compression. Conversely, A Thinner Wire Diameter Yields A More Flexible And Less Rigid Spring, Suitable For Applications Requiring Lower Forces Or Smaller Deflections.

The Selection Of The Wire Diameter Depends On Various Factors, Including The Desired Load Capacity, Available Space, And The Required Spring Rate (Force Per Unit Of Deflection). It Is Important To Strike A Balance Between The Wire Diameter And Other Design Parameters To Ensure The Spring Meets The Specific Requirements Of The Application.

Coil Diameter:

The Coil Diameter Of A Compression Spring Refers To The Outer Diameter Of The Spring When It Is In An Uncompressed State. It Represents The Overall Size Of The Spring And Is Typically Measured In Inches Or Millimeters. The Coil Diameter Is Determined By The Size Of The Mandrel Or Rod Around Which The Wire Is Wound During The Manufacturing Process.

The Coil Diameter Plays A Crucial Role In Determining The Physical Dimensions Of The Spring, Including Its Height, Outer Diameter, And Inner Diameter. It Also Affects The Number Of Active Coils In The Spring, Which Influences Its Overall Flexibility And Deflection Characteristics.

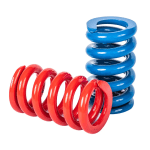

A Larger Coil Diameter Results In A Larger Outer Diameter And A Greater Number Of Active Coils, Which Can Provide A Higher Load Capacity And A Softer Spring Rate. Conversely, A Smaller Coil Diameter Yields A Smaller Outer Diameter And A Reduced Number Of Active Coils, Resulting In A Stiffer Spring With A Lower Load Capacity And A Higher Spring Rate.

The Selection Of The Coil Diameter Depends On Various Factors, Including The Available Space, The Desired Load Capacity, And The Required Spring Rate. It Is Important To Consider The Physical Constraints Of The Application And Ensure That The Chosen Coil Diameter Fits Within The Available Space While Providing The Desired Performance Characteristics.

In Summary, The Wire Diameter And The Coil Diameter Are Two Distinct Parameters That Define Different Aspects Of A Compression Spring. The Wire Diameter Determines The Thickness Of The Wire Used To Manufacture The Spring, Affecting Its Strength, Flexibility, And Load-Bearing Capacity. On The Other Hand, The Coil Diameter Represents The Outer Diameter Of The Spring In An Uncompressed State, Influencing Its Overall Size, Number Of Active Coils, And Deflection Characteristics. Both Parameters Are Crucial In Designing A Compression Spring That Meets The Specific Requirements Of The Application In Terms Of Load Capacity, Space Constraints, And Performance Characteristics.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!