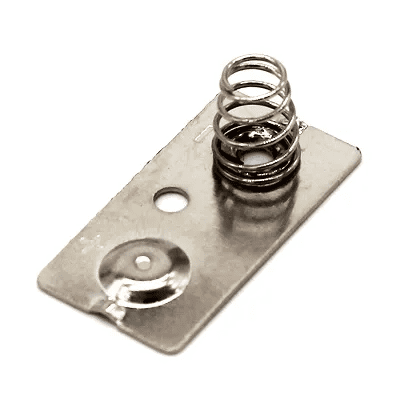

The Shear Force Of A Battery Contact Spring Refers To The Force Required To Deform Or Shear The Spring Material. While I’Ll Do My Best To Provide A Detailed Description, Please Note That The Actual Shear Force Of A Battery Contact Spring Can Vary Depending On The Specific Design And Material Properties.

Battery Contact Springs Are Typically Made Of Materials Like Stainless Steel Or Phosphor Bronze, Which Possess Excellent Mechanical Properties, Including High Strength And Elasticity. These Materials Are Chosen For Their Ability To Withstand The Forces And Deformations Experienced During The Spring’S Operation.

The Shear Force Of A Battery Contact Spring Is Influenced By Several Factors, Including The Material’S Shear Strength, The Spring’S Dimensions, And Its Design. Shear Strength Refers To The Maximum Stress A Material Can Withstand Before It Starts To Deform Or Fail In Shear.

To Understand The Shear Force Of A Battery Contact Spring, It’S Important To Consider The Spring’S Geometry. The Shear Force Is Primarily Determined By The Cross-Sectional Area Of The Spring Material That Is Subjected To Shear Stress. The Larger The Cross-Sectional Area, The Higher The Shear Force The Spring Can Withstand.

Manufacturers Carefully Design Battery Contact Springs To Ensure They Can Withstand The Expected Shear Forces Encountered During Their Operation. They Consider Factors Such As The Anticipated Loads, The Mechanical Properties Of The Spring Material, And The Desired Lifespan Of The Spring.

During The Operation Of A Battery Contact Spring, Shear Forces Can Arise From Various Sources. For Example, When A Battery Is Inserted Or Removed, The Spring May Experience Lateral Forces That Attempt To Deform Or Shear The Material. Additionally, External Factors Such As Vibrations, Impacts, Or Mechanical Stresses Can Also Contribute To The Shear Forces Acting On The Spring.

The Shear Force Of A Battery Contact Spring Is Typically Measured In Units Of Force, Such As Newtons (N) Or Pounds-Force (Lbf). The Specific Shear Force Required Can Vary Depending On The Application And The Expected Loads The Spring Will Encounter. Manufacturers Conduct Thorough Testing And Analysis To Determine The Appropriate Shear Force For Their Battery Contact Springs, Ensuring They Can Withstand The Anticipated Forces Without Deforming Or Failing.

It’S Worth Noting That While The Shear Force Is An Important Consideration For The Design And Durability Of A Battery Contact Spring, It Is Not Directly Related To The Spring’S Electrical Performance. The Shear Force Primarily Focuses On The Mechanical Integrity And Ability Of The Spring To Withstand External Forces Without Permanent Deformation Or Failure.

In Summary, The Shear Force Of A Battery Contact Spring Refers To The Force Required To Deform Or Shear The Spring Material. It Is Influenced By Factors Such As The Material’S Shear Strength, The Spring’S Dimensions, And Its Design. Manufacturers Carefully Design Battery Contact Springs To Withstand The Anticipated Shear Forces Encountered During Their Operation. The Shear Force Is Typically Measured In Units Of Force And Is Crucial For Ensuring The Mechanical Integrity And Durability Of The Spring.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!