Wire Forming Dies Are Essential Tools Used In The Manufacturing Industry To Shape And Form Wire Into Specific Designs And Configurations. These Dies Are Typically Made Of Hardened Steel And Are Used In Conjunction With A Press Or A Wire Forming Machine. They Provide The Necessary Force And Precision To Shape The Wire Accurately. Here, We Will Explore Some Of The Different Types Of Wire Forming Dies And Their Functionalities.

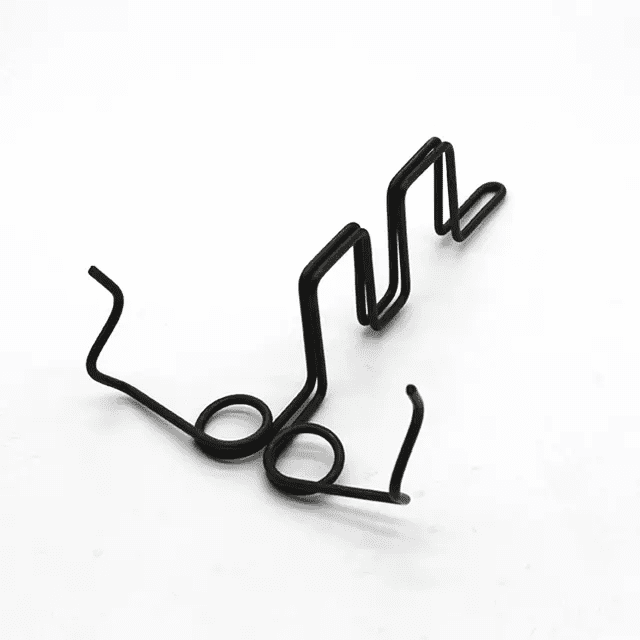

1. Bending Dies: Bending Dies Are Used To Create Bends And Curves In Wire. They Consist Of A Pair Of Matching Dies, One Fixed And One Movable, That Are Designed To Bend The Wire To A Specific Angle Or Radius. Bending Dies Can Be Customized To Create Various Shapes, Such As U-Bends, L-Bends, Or Complex Multi-Bend Configurations. They Are Commonly Used In Industries Such As Automotive, Furniture, And Hvac For Manufacturing Wire-Based Components.

2. Coiling Dies: Coiling Dies Are Used To Create Coils And Springs From Wire. They Consist Of A Set Of Cylindrical Or Conical Dies That Guide The Wire As It Is Wound Around Them. Coiling Dies Can Be Customized To Produce Different Coil Diameters, Pitches, And Shapes. They Are Commonly Used In Industries Such As Aerospace, Automotive, And Electronics For Manufacturing Springs, Connectors, And Other Wire-Based Components.

3. Forming Dies: Forming Dies Are Used To Shape Wire Into Specific Forms And Profiles. They Consist Of A Set Of Dies That Are Designed To Deform The Wire To The Desired Shape. Forming Dies Can Be Customized To Create Various Shapes, Such As Hooks, Loops, Eyelets, And Complex Geometries. They Are Commonly Used In Industries Such As Jewelry Making, Wire Forming, And Metal Fabrication.

4. Cutting Dies: Cutting Dies Are Used To Cut Wire Into Specific Lengths Or Shapes. They Consist Of A Pair Of Dies, One With A Cutting Edge And The Other With A Matching Recess. When The Wire Is Pressed Between The Dies, It Is Cut To The Desired Length Or Shape. Cutting Dies Can Be Customized To Produce Straight Cuts, Angled Cuts, Or Complex Shapes. They Are Commonly Used In Industries Such As Wire Manufacturing, Automotive, And Construction.

5. Swaging Dies: Swaging Dies Are Used To Reduce The Diameter Of Wire Or To Create Tapered Shapes. They Consist Of A Set Of Dies That Gradually Compress The Wire, Reducing Its Diameter Or Shaping It Into A Taper. Swaging Dies Can Be Customized To Produce Different Taper Angles And Lengths. They Are Commonly Used In Industries Such As Aerospace, Automotive, And Plumbing For Manufacturing Tapered Connectors, Fittings, And Wire-Based Components.

6. Piercing Dies: Piercing Dies Are Used To Create Holes Or Slots In Wire. They Consist Of A Pair Of Dies, One With A Sharp Cutting Edge And The Other With A Matching Recess. When The Wire Is Pressed Between The Dies, It Is Pierced, Creating A Hole Or Slot. Piercing Dies Can Be Customized To Produce Different Hole Sizes And Shapes. They Are Commonly Used In Industries Such As Electronics, Jewelry Making, And Wire Forming.

7. Embossing Dies: Embossing Dies Are Used To Create Raised Or Recessed Patterns On The Surface Of Wire. They Consist Of A Set Of Dies With Engraved Patterns That Are Pressed Onto The Wire, Imprinting The Desired Design. Embossing Dies Can Be Customized To Produce Various Patterns, Logos, Or Text. They Are Commonly Used In Industries Such As Jewelry Making, Decorative Wirework, And Branding.