Stamping Parts for Benefits?

Stamped Parts Offer Numerous Benefits In Various Industries, Thanks To Their Versatility, Cost-Effectiveness, And Efficiency. Whether It’S In Automotive, Aerospace, Electronics, Or Other Sectors, Stamped Parts Play A Crucial Role In Manufacturing Processes.

1. Cost-Effectiveness: Stamped Parts Are Highly Cost-Effective Due To Their Efficient Production Process. The Stamping Method Allows For High-Volume Production, Reducing Per-Unit Costs Significantly.

Additionally, The Use Of Automated Machinery And Progressive Die Systems Further Enhances Cost Savings. This Makes Stamped Parts An Attractive Option For Industries That Require Large Quantities Of Components.

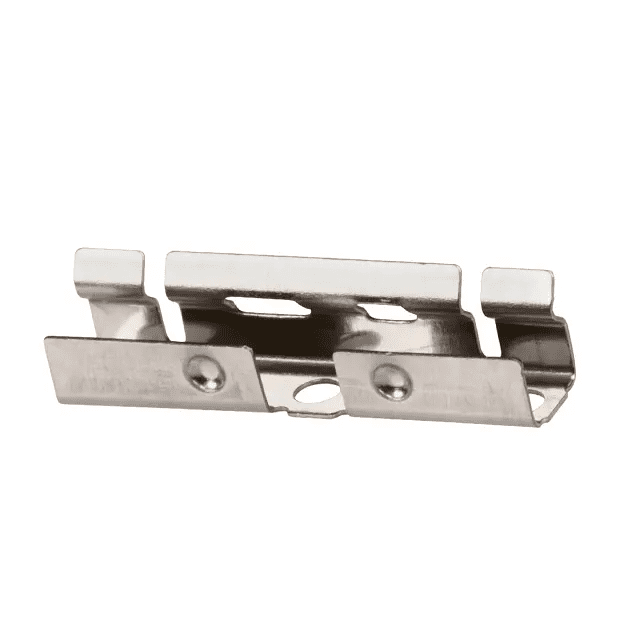

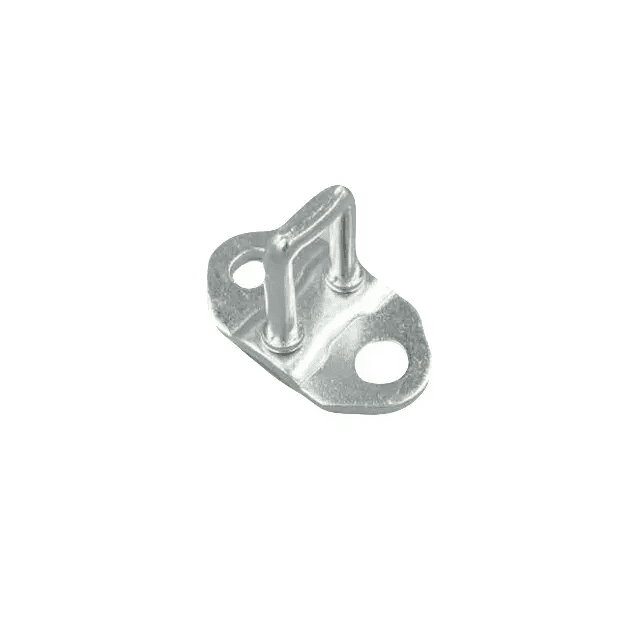

2. Versatility: Stamped Parts Can Be Manufactured In A Wide Range Of Shapes, Sizes, And Materials. The Stamping Process Allows For The Creation Of Complex Geometries, Intricate Designs, And Tight Tolerances. W

hether It’S Simple Brackets, Intricate Connectors, Or Complex Automotive Body Panels, Stamped Parts Can Be Tailored To Meet Specific Requirements. This Versatility Makes Them Suitable For Various Applications Across Industries.

3. Speed And Efficiency: Stamping Is A Highly Efficient Manufacturing Process That Enables Rapid Production. With The Use Of Automated Machinery, Stamping Can Produce Parts At High Speeds, Ensuring Quick Turnaround Times.

The Ability To Produce Multiple Parts Simultaneously Further Enhances Efficiency. This Makes Stamped Parts Ideal For Industries With Tight Production Schedules And High Demand.

4. Consistency And Precision: Stamped Parts Offer Exceptional Consistency And Precision. The Use Of Progressive Dies Ensures That Each Part Is Produced With The Same Level Of Accuracy, Maintaining Uniformity Throughout The Production Run.

This Consistency Is Crucial In Industries Where Precise Dimensions And Tight Tolerances Are Required, Such As Aerospace And Electronics.

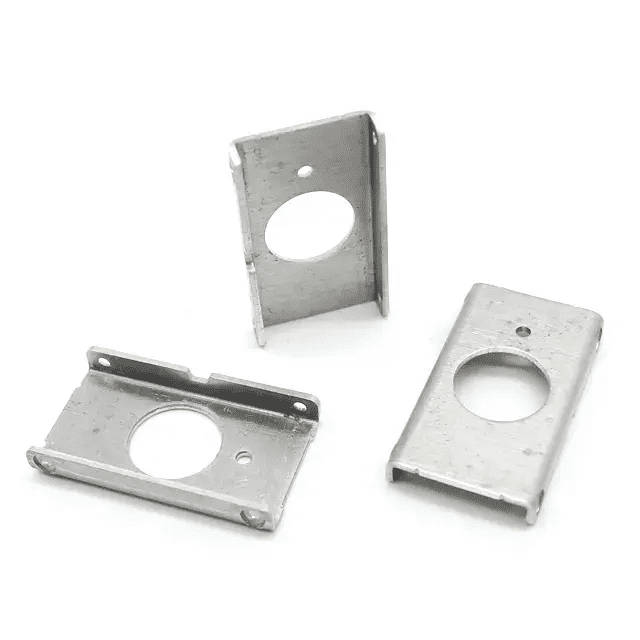

5. Strength And Durability: Stamped Parts Are Known For Their Strength And Durability. The Stamping Process Compresses The Material, Resulting In Parts That Are Resistant To Deformation And Capable Of Withstanding High Loads.

This Makes Stamped Parts Suitable For Applications That Require Robust Components, Such As Automotive Chassis, Structural Supports, And Industrial Machinery.

6. Material Options: Stamped Parts Can Be Manufactured From A Wide Range Of Materials, Including Various Metals And Alloys. Common Materials Used In Stamping Include Steel, Aluminum, Copper, And Stainless Steel. The Ability To Choose From Different Materials Allows Manufacturers To Select The Most Suitable Option Based On Factors Such As Strength, Corrosion Resistance, And Conductivity.

7. Integration With Other Processes: Stamped Parts Can Easily Integrate With Other Manufacturing Processes. They Can Be Further Processed Through Welding, Assembly, Or Surface Finishing Techniques To Meet Specific Requirements.

This Flexibility Allows For Seamless Integration Into Larger Assemblies Or Systems, Reducing The Need For Additional Manufacturing Steps.

8. Reduced Waste: The Stamping Process Minimizes Material Waste Due To Its Precision And Efficiency. The Use Of Progressive Dies Ensures That Material Utilization Is Optimized, Resulting In Minimal Scrap.

Additionally, The Ability To Produce Multiple Parts From A Single Sheet Of Material Further Reduces Waste. This Makes Stamped Parts An Environmentally Friendly Option, Aligning With Sustainable Manufacturing Practices.

9. Design Flexibility: Stamped Parts Offer Design Flexibility, Allowing For The Creation Of Custom Components. The Stamping Process Can Accommodate Various Design Features, Such As Embossing, Coining, And Forming.

This Flexibility Enables Manufacturers To Create Unique Parts That Meet Specific Functional And Aesthetic Requirements.

10. Quality Control: Stamped Parts Undergo Rigorous Quality Control Measures To Ensure Their Reliability And Performance. Advanced Inspection Techniques, Such As Automated Vision Systems, Are Employed To Detect Any Defects Or Inconsistencies. This Ensures That Only High-Quality Parts Are Delivered To Customers, Reducing The Risk Of Failures Or Malfunctions.

In Conclusion, Stamped Parts Offer A Multitude Of Benefits, Including Cost-Effectiveness, Versatility, Speed, Precision, Strength, And Integration Capabilities.

Their Ability To Accommodate Various Materials, Design Features, And Manufacturing Processes Makes Them Indispensable In Numerous Industries. Whether It’S For Mass Production Or Custom Components, Stamped Parts Provide A Reliable And Efficient Solution For Manufacturers Worldwide.

I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!