What Is The Maximum Fatigue Life Of A Tension Spring?

The Maximum Fatigue Life Of A Tension Spring Depends On Various Factors Such As The Material Used, The Design Of The Spring, The Applied Load, And The Operating Conditions.

While I Can Provide You With A General Description, It’S Important To Note That Specific Calculations And Considerations Are Necessary For Accurate Fatigue Life Estimation.

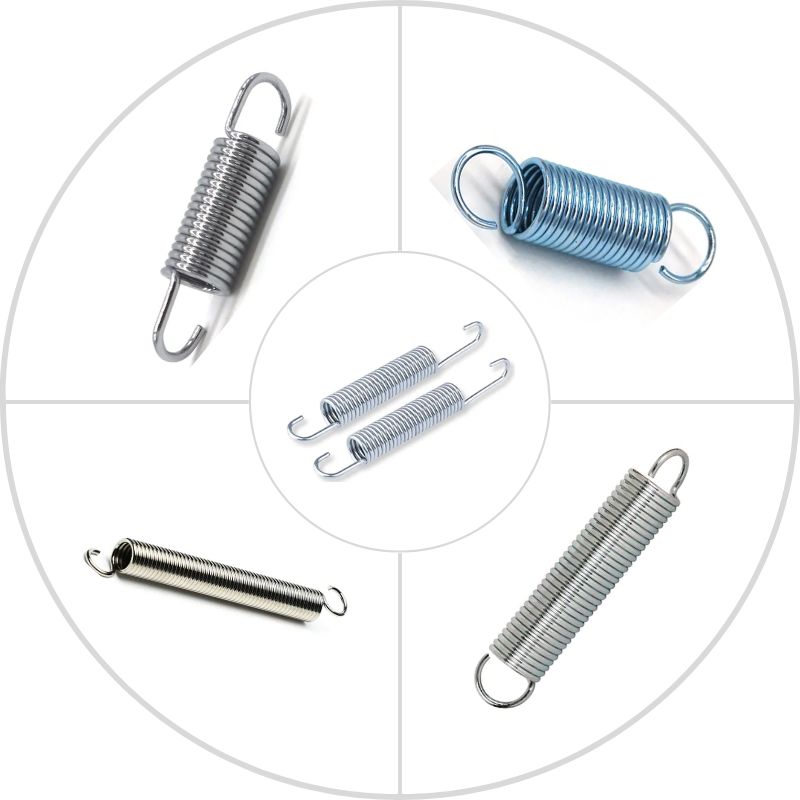

Tension Springs Are Mechanical Components Designed To Absorb And Store Energy When Subjected To A Pulling Or Tensile Force.

They Are Commonly Used In A Wide Range Of Applications, Including Automotive, Aerospace, Industrial Machinery, And Consumer Products.

The Fatigue Life Of A Tension Spring Refers To The Number Of Cycles Or Times The Spring Can Endure Before Failure Occurs Due To Fatigue.

Fatigue Failure Typically Happens When A Material Undergoes Repeated Cyclic Loading, Leading To The Initiation And Propagation Of Cracks, Ultimately Resulting In Failure.

To Estimate The Maximum Fatigue Life Of A Tension Spring, Engineers Consider Several Factors:

1. Material: The Choice Of Material Is Crucial As Different Materials Have Varying Fatigue Properties.

Common Materials Used For Tension Springs Include High-Carbon Steel, Stainless Steel, And Various Alloys. Each Material Has Its Own Fatigue Strength And Endurance Limit, Which Determines Its Ability To Withstand Cyclic Loading.

2. Design: The Design Of The Tension Spring Plays A Significant Role In Its Fatigue Life. Factors Such As Wire Diameter, Coil Pitch, Number Of Active Coils, And The Presence Of Stress-Relieving Processes Can Affect The Spring’S Ability To Resist Fatigue Failure.

Proper Design Considerations, Such As Minimizing Stress Concentrations And Optimizing The Spring’S Geometry, Can Enhance Its Fatigue Life.

3. Load And Stress: The Applied Load And Stress Levels Experienced By The Tension Spring Are Critical Factors In Determining Its Fatigue Life.

Engineers Analyze The Maximum And Minimum Loads, As Well As The Stress Amplitudes And Mean Stress Levels, To Calculate The Fatigue Life Using Various Fatigue Analysis Methods Such As Stress-Life (S-N) Curves Or Strain-Life (ε-N) Curves.

4. Operating Conditions: The Environmental Conditions In Which The Tension Spring Operates Also Impact Its Fatigue Life.

Factors Such As Temperature, Humidity, Corrosion, And Vibration Can Accelerate Fatigue Failure. Proper Lubrication, Protective Coatings, And Environmental Controls Can Help Mitigate These Effects And Extend The Spring’S Fatigue Life.

Given The Complexity And Variability Of These Factors, It Is Challenging To Provide A Specific Maximum Fatigue Life For A Tension Spring Without Detailed Information About The Specific Application And Design Parameters.

Engineers Typically Perform Fatigue Analysis And Testing To Estimate The Fatigue Life Accurately.

In Conclusion, The Maximum Fatigue Life Of A Tension Spring Is Influenced By Material Properties, Design Considerations, Applied Load And Stress, And Operating Conditions.

To Determine The Specific Fatigue Life For A Given Tension Spring, It Is Essential To Consult With An Experienced Engineer Who Can Perform Detailed Calculations And Analysis Based On The Specific Requirements And Parameters Of The Application.

Xiamen Hongsheng Spring focus on hardware products, Springs(Tension Spring), stamping parts and other hardware manufacturing for nearly 20 years, with a high-quality team, certification through ISO and IATF certificates, won the industry praise;

our slogan is Be Hongsheng Springs,Be Specialist, Our goal is to become a manufacturer of precision hardware springs through cutting-edge technology to create higher quality.I Wish Everyone Can Find Their Own Hardware Accessories, Xiamen Hongsheng Spring Welcome Your Choice!