Foundational processes are more important than ever in the world of sophisticated manufacturing where the margin of error is reducing each day. The metal wire forming is one of them, and a very significant sphere, which directly impacts the performance, stability and effectiveness of high-precision components. In any industry where a fraction of a millimeter or a gram of force may mean success or failure the study and the art of this should not be only advantageous, but absolutely necessary.

The invisible Support of Precision Engineering

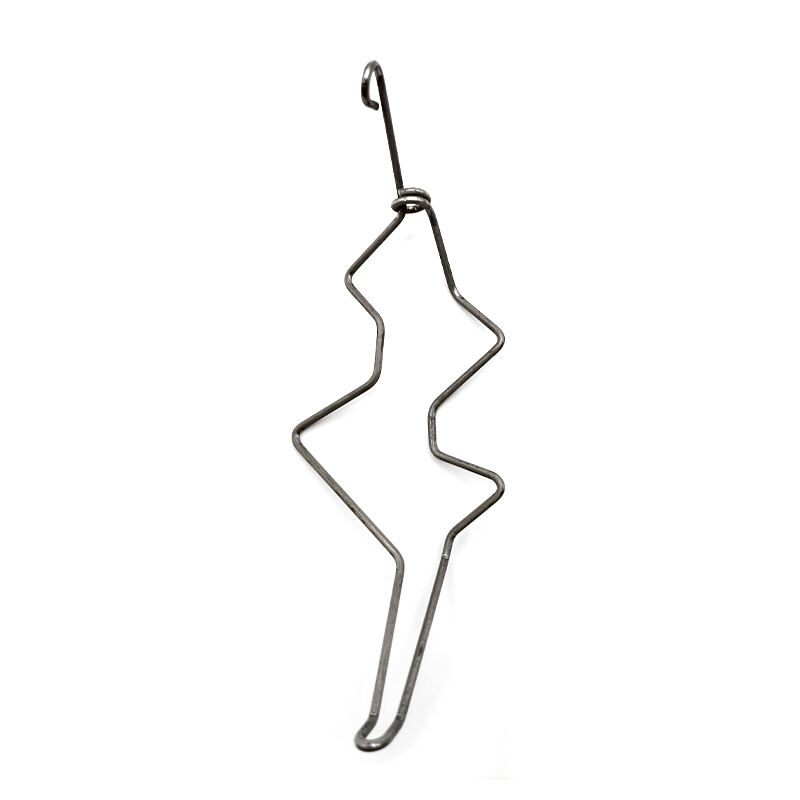

The high-precision components are characterized by their high tolerances, repeatability, and constant reliability within certain conditions. They are not just metal items, they are functional items designed to perform a particular, often important, task within a greater system. The technique by which the raw wire is converted into these complicated, two- or three-dimensional forms is metal wire forming; an all-metallic process. Bending It goes way beyond mere bending. It engages profound knowledge on material behavior, physics and sophisticated tooling to produce parts that are accurate in their geometric and functional requirements. When properly done, such a process results in components that are reproducible, robust, and optimally adapted to their purpose, the hidden tool behind it all, medical equipment and delicate electronic mechanisms.

Addressing the Strict Requirements of the modern applications

Industries that are technologically on the frontline generate the need to have high-precision components. These industries need components that are able to operate reliably in harsh conditions, dynamic loads, and consistent integrity with millions of cycles. Ready-made solutions that are available in the market usually fail here. Metal wire forming is an effective way of tackling these issues. It has made it possible to develop components with precise spring rates, desired contact geometries and customized force- deflection behavior. Such customization means that the resulting component will fit perfectly into the assembly giving the desired mechanical behavior, be it constant tension, shock absorption, or a sure electrical contact. Unless the forming process is precise, the component is the weakest link and this may compromise the performance of the whole system.

A Hongsheng Precision Forming Approach

In Xiamen Hongsheng Hardware Spring Co., Ltd., we will be addressing the issue of taking metal wire forming as a production process to an aspect of precision engineering. We have made it our specialty to utilize this process in order to create high accuracy springs and formed wire parts. We acknowledge the fact that the accuracy is obtained as a result of a combination of professional design, regulated procedures, and scrupulous validation. We plan to do it through collaborative design support to optimize the geometry of parts both in their functions and their manufacturability, and then apply specialized CNC forming technology. The technology can guarantee that all bends, coils and angles are duplicated with a high degree of precision when working with large batch production. Moreover, we are also committed to high-level process and final inspection to ensure such imperative parameters as dimensions, load, and stress are met and surpass the high standards of high-precision applications.

Innovating by Finding Excellence

Finally, the significance of metal wire forming can be found in the fact that it allows innovation. It gives the engineers and designers high-performance precision springs and components that are reliable and enable them to challenge the limits of what can be done with product design. It is a basic technology that facilitates developments in several industries. This is what we mean by Xiamen Hongsheng Hardware Spring Co., Ltd. mission. We will strive to master the art of metal wire forming, and we will make certain to provide our customers with elements that bring uncompromising precision, durability and value. Even in the quest to achieve engineering excellence, the quality of the smallest part is all and it all starts with the art of forming process.