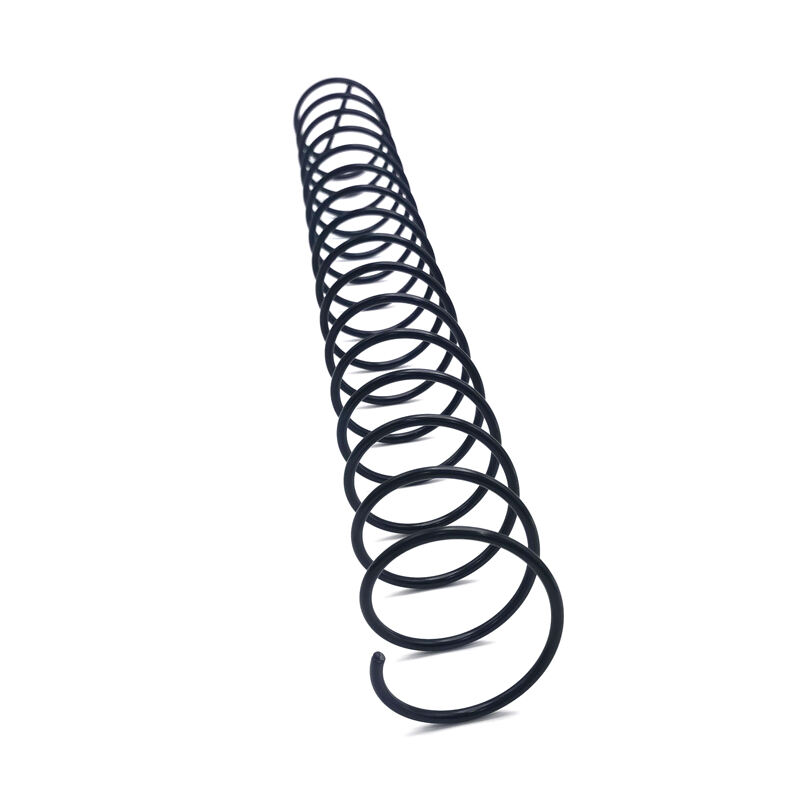

One of the most basic but also highly important elements of mechanical systems is the springs. Although an ordinary spring can be used to fulfill a wide range of tasks, modern automotive and aerospace engineering exerts its toll on a spring, which frequently requires a different solution: custom springs. These are not off-the-shelf, but are custom-designed, down to the last detail, to fit a particular performance, environmental and spatial requirement.

The Critical Need for Customization

The motivation of customization is driven by the performance of unmatched performance in these industries. A universal solution will never be able to provide the needed reliability, efficiency, or safety.

Precision Performance Requirements

Parameters are different in every application. In the case of automotive systems, this can be a definite load rate that will provide the best ride and handling. In the aerospace industry, it might entail developing a spring that functions perfectly in the presence of the high pressure and changes in temperature. Individual springs are developed with specific load-deflection curves, fatigue life, as well as operating limits.

Space and Weight Constraints

This is particularly true of aerospace where every gram and every millimeter matters. A spring that is going to fit in a highly tight and irregularly shaped envelope is also usually required of engineers, and it helps in the overall reduction of weight. Custom design Custom design enables development of springs with unusual geometry which is able to be created with minimal space and yet maximize performance.

Material Science in Spring Design

The material is determined by the environment. The springs off-the-shelf are usually constructed of music wire or stainless steel. However, custom springs make use of a much wider range of high-technology materials.

Meeting Extreme Environments

In under-the-hood automotive use, or landing gear in aerospace, springs have to resist both corrosion and high temperature as well as continuous vibration. This may involve special alloy such as Inconel or Elgiloy which has a great resistance to heat and corrosion. The choice of a material is part of the long-term service and working without failures.

The Design and Manufacturing Process

Design of a custom spring is a communal and a repetitive procedure involving an engineer and the spring manufacturer.

Advanced Modeling and Simulation

This starts with the advanced computer modeling and finite element analysis (FEA). This computer based prototyping enables the engineers to test the performance of the spring under actual loads and stresses of the real world and also their probable failure points are identified well before a real prototype is ever made. This is an important step of the design validation and compliance by meeting all the safety and performance requirements.

Precision Manufacturing Techniques

After the design is complete, it is manufactured on state of the art CNC coiling and precision grinding equipment. This makes every spring to be made to an exact specification with uniform wire diameter, pitch and overall geometry. Intensive quality control and testing that comprise stress relief and pre set processes ensure that the end product works as intended during its entire service life.